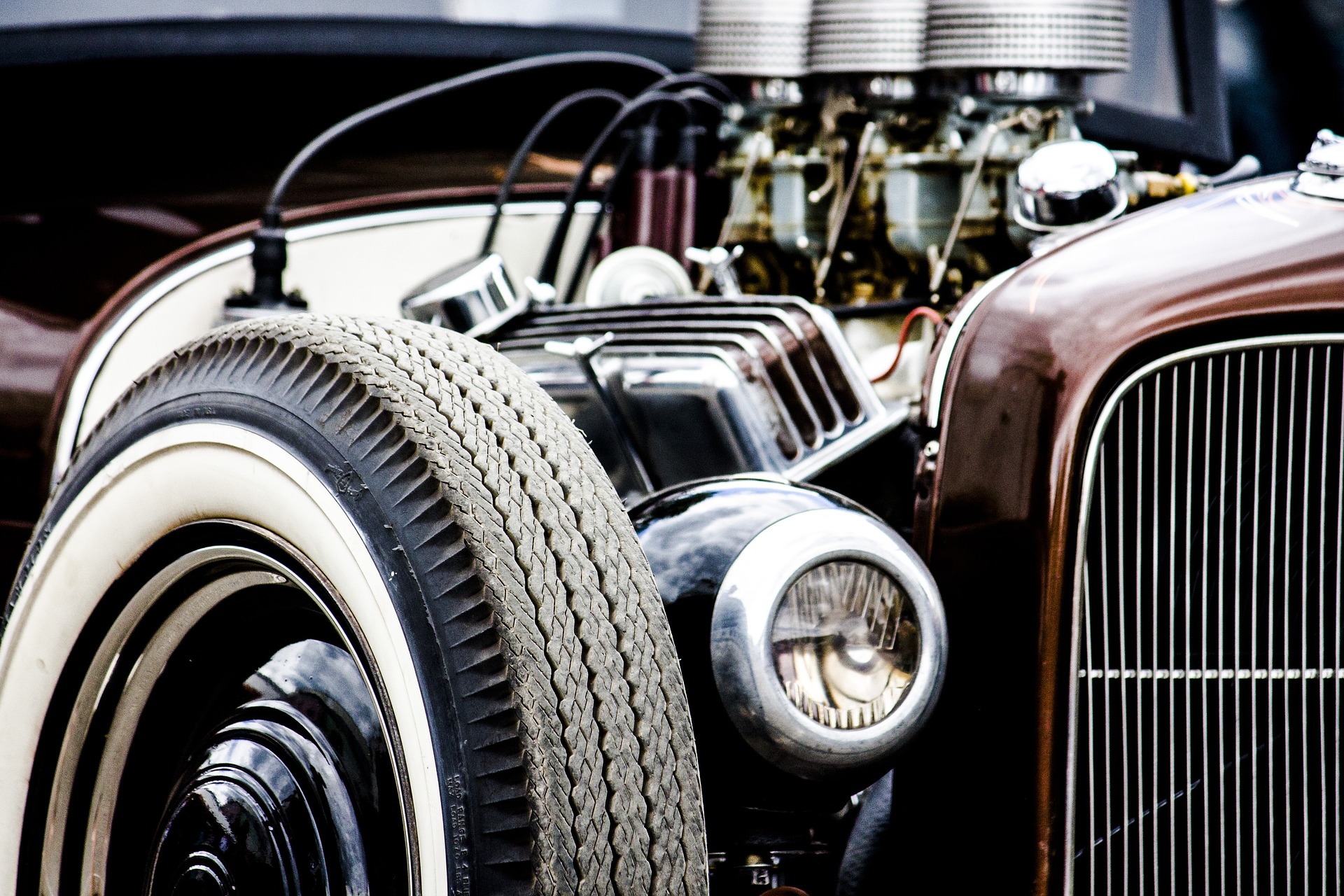

The Forgotten Art of Carburetor Tuning

Carburetors, once the heartbeat of every automobile engine, have largely faded into obscurity in the age of fuel injection. Yet, for classic car enthusiasts and performance purists, the art of carburetor tuning remains a vital skill. This intricate dance of air and fuel mixture optimization not only keeps vintage engines running smoothly but can unlock hidden potential in these mechanical marvels. Let's dive into the world of carburetor tuning, exploring its nuances, challenges, and the satisfaction it brings to those who master it.

Despite their complexity, carburetors began to lose ground to fuel injection systems in the 1980s. Fuel injection offered more precise control over fuel delivery, better fuel efficiency, and lower emissions. However, carburetors continued to be used in some vehicles well into the 1990s, particularly in developing markets and in certain performance applications.

The Basics of Carburetor Function

At its core, a carburetor operates on the Bernoulli principle. As air flows through the carburetor, it creates a pressure drop. This pressure differential draws fuel from the float bowl into the airstream, creating a combustible mixture. The mixture then flows into the engine’s cylinders for combustion.

Carburetors typically have several circuits to handle different operating conditions:

-

Idle circuit: Provides fuel at low engine speeds

-

Main circuit: Handles normal driving conditions

-

Power enrichment circuit: Supplies extra fuel under high load

-

Accelerator pump: Provides a quick shot of fuel during acceleration

-

Choke: Enriches the mixture for cold starts

Each of these circuits must be carefully adjusted to achieve optimal performance across all driving conditions.

The Art of Tuning

Carburetor tuning is as much an art as it is a science. It requires a deep understanding of engine behavior, a keen ear, and often, a fair bit of patience. The goal is to achieve the perfect air-fuel ratio for every operating condition, from idle to full throttle.

The process typically begins with setting the idle mixture and speed. This involves adjusting the idle mixture screw and idle speed screw until the engine runs smoothly at idle. Next, the main jet size is adjusted to ensure proper fuel delivery under normal driving conditions. The power valve and accelerator pump are then fine-tuned for performance under heavy load and during acceleration.

One of the most challenging aspects of carburetor tuning is achieving a smooth transition between the various circuits. A well-tuned carburetor should provide seamless power delivery from idle to redline, with no hesitation or stumbling.

Tools of the Trade

While experienced tuners can often make adjustments by ear, several tools can aid in the process:

-

Vacuum gauge: Helps diagnose air leaks and improper mixture settings

-

Tachometer: Essential for setting idle speed and monitoring engine RPM during tuning

-

Air-fuel ratio meter: Provides real-time feedback on mixture composition

-

Chassis dynamometer: Allows for precise measurement of power output during tuning

These tools, combined with a good understanding of engine behavior, can help achieve optimal performance from a carbureted engine.

The Challenges of Carburetor Tuning

Carburetor tuning is not without its challenges. Unlike modern fuel injection systems, carburetors are susceptible to changes in altitude, temperature, and humidity. A perfectly tuned carburetor at sea level may run rich at high altitudes due to the thinner air.

Additionally, carburetors require regular maintenance to perform optimally. Dirt, varnish, and wear can all affect carburetor performance, necessitating periodic cleaning and rebuilding.

Perhaps the biggest challenge in carburetor tuning is the increasing scarcity of knowledge and parts. As fuel injection has become ubiquitous, fewer mechanics are trained in carburetor tuning, and parts can be difficult to source for some models.

The Future of Carburetor Tuning

Despite the challenges, carburetor tuning remains an important skill in certain niches. Classic car restoration, vintage racing, and some forms of motorsport still rely heavily on carbureted engines. In these fields, the ability to extract maximum performance from a carburetor is highly valued.

Moreover, there’s a growing interest in preserving these mechanical skills. Some enthusiasts are turning to carbureted engines as a way to connect with automotive history and to understand the fundamental principles of engine operation.

Interestingly, modern technology is also finding its way into the world of carburetors. 3D printing has made it possible to reproduce rare or obsolete carburetor parts, while computer modeling can aid in designing more efficient carburetor systems for specific applications.

As we move further into the age of electric vehicles and advanced fuel injection systems, the art of carburetor tuning stands as a testament to the ingenuity of early automotive engineers. It remains a valuable skill, connecting us to the roots of automotive technology while still offering lessons in the fundamental principles of engine operation.